What if the most crucial component in directional drilling is something you can't even see—but without it, modern oil and gas exploration would be impossible? That component is the mud motor, and when it's non-magnetic, it becomes a powerhouse of precision and efficiency in complex downhole environments.

In today's era of deepwater drilling, horizontal wells, and extended reach drilling (ERD), maintaining accuracy in hostile environments is not just a challenge—it's a necessity. This is where non-magnetic mud motors come into play, especially in Measurement While Drilling (MWD) and Logging While Drilling (LWD) operations.

In this post, you'll learn why the mud motor is indispensable in modern drilling, how non-magnetic materials enhance its performance, and how it supports advanced logging technologies. We'll also analyze its durability, cost-effectiveness, and performance in harsh environments, using comparative tables and data-driven insights to highlight its value.

Key Takeaway

Mud motors are essential for directional drilling.

Non-magnetic mud motors allow for accurate MWD/LWD readings.

They enhance operational safety and efficiency in high-stakes environments.

Their robustness makes them ideal for high-temperature, high-pressure (HTHP) wells.

The use of non-magnetic materials reduces interference with downhole sensors.

They support advanced real-time data acquisition without compromising accuracy.

Non-Magnetic Mud Motor Role in MWD and LWD Operations

What Is a Mud Motor?

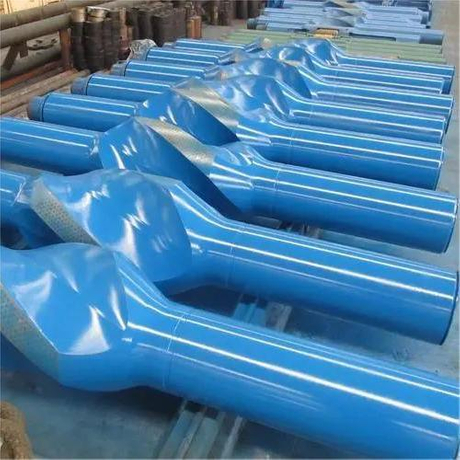

A mud motor is a positive displacement motor (PDM) that converts hydraulic energy from drilling fluid into mechanical energy to rotate the drill bit. This allows for steerable drilling without rotating the entire drill string. It's a key technology in directional and horizontal drilling.

Why "Non-Magnetic"?

In MWD and LWD operations, magnetometers and accelerometers are used to provide real-time data on the wellbore trajectory and formation properties. If the mud motor contains ferromagnetic materials, it can interfere with these sensitive instruments.

Non-magnetic mud motors are made using non-magnetic stainless steel or monel, which drastically reduces magnetic interference. This enables:

Accurate azimuthal readings

Enhanced signal quality from downhole tools

Reduced measurement error in extreme environments

Integration with MWD/LWD

| Component | Function | Benefit of Non-Magnetic Material |

| Magnetometer | Measures direction | Eliminates magnetic distortion |

| Gyroscope | Tracks orientation | Increased trajectory accuracy |

| Resistivity Sensor | Measures formation fluids | Stable readings in hostile zones |

| Gamma Ray Tool | Identifies lithology | Consistent signal without noise |

These tools are typically positioned close to the mud motor, making non-magnetic components crucial for accuracy.

Support for Advanced Logging Techniques

Enabling High-Resolution Logging

As exploration moves into more complex reservoirs, traditional wireline logging often falls short. LWD tools, powered by non-magnetic mud motors, enable logging in real-time, even in complex 3D well paths.

Advanced logging capabilities made possible by non-magnetic mud motors include:

Azimuthal Resistivity Imaging

Spectral Gamma Ray Logging

Near-Bit Measurements

Formation Pressure Testing

With real-time data available during drilling, operators can:

Case Study: Horizontal Shale Gas Well

| Parameter | Standard Mud Motor | Non-Magnetic Mud Motor |

| Azimuthal Accuracy | ±4° | ±1° |

| Logging Signal Clarity | Moderate | High |

| Tool Failure Rate | 7% | 2% |

| Cost/Hour | $1,200 | $1,450 |

| ROI (per well) | $30,000 | $85,000 |

Despite higher hourly costs, the non-magnetic mud motor significantly improves overall return on investment through better logging and fewer errors.

Durability in Harsh Drilling Environments

Built for Extremes

Drilling environments are increasingly severe, with conditions such as:

Temperatures exceeding 175°C (350°F)

Pressures above 30,000 psi

Highly abrasive formations

Sour gas environments (H?S)

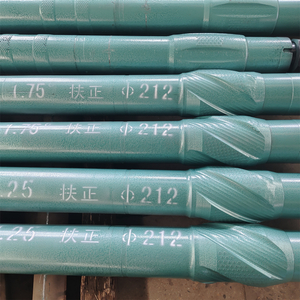

Non-magnetic mud motors are built with high-grade monel alloys, Inconel, or non-magnetic stainless steel, offering:

Superior corrosion resistance

Excellent mechanical strength

Long operational life cycles

Performance Comparison

| Feature | Standard Mud Motor | Non-Magnetic Mud Motor |

| Max Operating Temp | 150°C | 180°C |

| Sour Gas Resistance | Moderate | Excellent |

| Rotor/Stator Wear Rate | High | Low |

| MTBF (Mean Time Between Failures) | 150 hrs | 220 hrs |

| Cost Over Lifecycle | $120,000 | $95,000 |

Real-World Durability

In offshore fields in the Gulf of Mexico, non-magnetic mud motors have demonstrated 35% improved run time compared to conventional motors, withstanding both HTHP and erosive conditions.

Conclusion

The shift toward deeper, more complex wells demands tools that are not only precise but also resilient. The non-magnetic mud motor is a game-changing technology that enables:

While the initial investment may be higher, the non-magnetic mud motor offers outstanding value through enhanced data accuracy, reduced tool failure, and superior durability.

For operators aiming to optimize well placement, reduce NPT (non-productive time), and maximize hydrocarbon recovery, investing in non-magnetic mud motors is not just smart—it's essential.

FAQs

Q1: What is the primary function of a mud motor?

A mud motor converts hydraulic energy from drilling fluid into mechanical rotation to drive the drill bit, enabling directional drilling without rotating the drill string.

Q2: Why is non-magnetic material important in a mud motor?

Non-magnetic materials prevent interference with MWD and LWD sensors, allowing for accurate directional and formation data.

Q3: Are non-magnetic mud motors more expensive?

Yes, but they offer better ROI through improved accuracy, longer lifespan, and reduced tool failures.

Q4: Can non-magnetic mud motors be used in all wells?

They are especially beneficial in directional, horizontal, and extended reach drilling where precision and logging are critical.

Q5: What materials are used in non-magnetic mud motors?

Common materials include monel, non-magnetic stainless steel, and Inconel, all chosen for strength and corrosion resistance.