Did you know that even the most advanced drill bits can fail if the drill string lacks proper stabilization? Drilling stabilizers are unsung heroes in the drilling industry, operating behind the scenes to ensure smoother operations, reduce tool wear, and improve borehole quality. Without them, drilling becomes inefficient, expensive, and prone to failure.

In complex drilling environments—such as deepwater, shale, or high-deviation wells—wellbore stability and tool alignment are non-negotiable. This is where drilling stabilizers come in, playing a crucial role in maintaining directional control and prolonging equipment life.

In this post, you'll learn what a drilling stabilizer is, discover its various types, understand how placement affects performance, and explore how to choose the right stabilizer for your project. We'll cover technical details, design considerations, performance comparisons, and real-world applications—everything you need to know before making a purchase or operational decision.

Key Takeaway

A drilling stabilizer is a crucial component in the bottom hole assembly (BHA), used to stabilize the drill string and prevent unintentional deviation.

There are several types of stabilizers, including integral blade, welded blade, replaceable sleeve, replaceable blade, non-rotating, and roller reamer types.

Proper selection and placement of stabilizers significantly affect drilling efficiency, cost, and wellbore quality.

Design features such as blade geometry, hardfacing, and under-gauge options are critical in determining performance in specific formations.

This guide offers a comprehensive analysis of stabilizer types, selection strategies, and performance metrics.

Main Types of Drilling Stabilizer and Their Characteristics

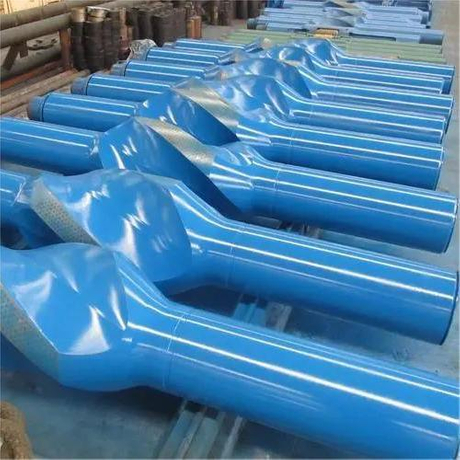

Integral Blade Drilling Stabilizer

An integral blade drilling stabilizer is machined from a single piece of steel, making it extremely robust and suitable for high-load applications.

Characteristics:

High durability and resistance to fatigue

No welds or joints, reducing failure risks

Typically used in high-pressure, high-temperature (HPHT) environments

Applications: Deep wells, abrasive formations, offshore drilling

Welded Blade Drilling Stabilizer

In this type, blades are welded onto a solid body, offering a balance between cost and performance.

Characteristics:

Lower cost than integral models

Customizable blade geometry

More prone to blade detachment under extreme loads

Applications: Medium-depth drilling, directional wells

Replaceable Sleeve Drilling Stabilizer

These stabilizers feature a replaceable sleeve around the body, which can be changed out after wear—making them highly economical in the long term.

Characteristics:

Reduces downtime and cost

Ideal for soft to medium-hard formations

Allows for multiple re-runs with the same body

Applications: Land rigs, maintenance-focused operations

Replaceable Blade Drilling Stabilizer

Instead of replacing the sleeve, this design allows for blade replacement, which is useful when only the cutting elements are worn.

Characteristics:

Applications: Remote locations, operations with limited tool inventory

Non-Rotating Drilling Stabilizer

These stabilizers feature a sleeve that doesn't rotate with the drill string, reducing torque and drag, especially in deviated or horizontal wells.

Characteristics:

Applications: Directional and horizontal drilling operations

Roller Reamer as a Drilling Stabilizer

Though primarily a reaming tool, the roller reamer also serves as a stabilizer by keeping the bit centered and enlarging tight spots in the borehole.

Characteristics:

Combines reaming and stabilization

Reduces doglegs and borehole spiraling

Includes rolling cutters for smoother borehole walls

Applications: Hard formations, extended-reach wells

Drilling Stabilizer Placement and Design Considerations

Near-Bit Drilling Stabilizer

Placed just above the drill bit, the near-bit stabilizer ensures that the bit stays centered, reducing vibration and improving bit life.

Benefits:

Enhances directional control

Improves hole straightness

Reduces bit whirl and stick-slip

In-String Drilling Stabilizer

Placed further up the drill string, in-string stabilizers maintain borehole trajectory and reduce buckling in long drill strings.

Benefits:

Blade Design Options

Blade design significantly impacts performance. Common options include:

| Blade Type | Application | Pros | Cons |

| Straight Blades | Vertical wells | Simpler design, easy to manufacture | Less effective in deviated wells |

| Spiral Blades | Deviated or directional wells | Better borehole contact | Higher manufacturing cost |

| Chevron Blades | Soft formations | Gentle cutting action | Limited use in hard formations |

Blade width and angle also affect cuttings transport and hole cleaning efficiency.

Hardfacing Technology

Hardfacing involves applying wear-resistant materials to the blade surface, increasing tool longevity. Materials include:

Tungsten carbide: For hard formations

Diamond-enhanced materials: For extreme wear resistance

Nickel-based alloys: Corrosion-resistant

Under-Gauge Design

Under-gauge stabilizers are slightly smaller in diameter than the hole size, reducing torque and drag.

Use Cases:

How Drilling Stabilizer Improves Drilling Efficiency and Hole Quality

A properly selected and placed drilling stabilizer improves multiple aspects of the drilling process:

1. Minimizes Unintentional Deviation

By keeping the BHA centered, stabilizers prevent doglegs and spiraling, which can cause tool failure and increased drilling costs.

2. Reduces Tool and Bit Wear

With less vibration and bit bouncing, stabilizers extend the life of the drill bit and MWD tools.

3. Enhances Hole Cleaning

Spiral or chevron blades improve fluid circulation, helping remove cuttings more effectively.

4. Increases Rate of Penetration (ROP)

A stabilized assembly allows for higher WOB, improving ROP while keeping the borehole quality high.

Statistical Insight

| With Stabilizer | Without Stabilizer |

| 20–35% increase in ROP | Higher risk of deviation |

| 40% longer bit life | Increased tool failure |

| 30% reduction in NPT (non-productive time) | More reaming required |

Selection Criteria for a Drilling Stabilizer

When choosing a drilling stabilizer, consider the following factors:

1. Formation Type

2. Hole Size

Match the OD (outer diameter) of the stabilizer to the wellbore size. Undersized tools can cause vibration, while oversized tools increase drag.

3. Drilling Direction

4. Budget and Lifecycle Cost

Though integral stabilizers are expensive, they provide greater durability. Replaceable types offer a lower cost-per-run.

5. Tool Compatibility

Ensure that the stabilizer is compatible with the BHA design, especially with MWD/LWD tools and mud motors.

Conclusion

The drilling stabilizer is more than just a passive component—it's a performance enhancer, a cost reducer, and a key to borehole quality. By selecting the right type, blade design, and placement strategy, operators can significantly boost drilling efficiency, reduce non-productive time, and improve bit life.

As drilling environments become more complex, the role of stabilizers will only grow in importance. With new materials, smart sensors, and adaptive designs on the horizon, the future of drilling stabilization technology is promising and evolving.

FAQs

Q1: What is the lifespan of a drilling stabilizer?

A high-quality stabilizer can last for 500–1,000 drilling hours, depending on formation type and hardfacing.

Q2: Can I use more than one stabilizer in a BHA?

Yes, combining near-bit and in-string stabilizers enhances directional control and reduces vibration.

Q3: What's the difference between a stabilizer and a reamer?

A stabilizer centers the BHA, while a reamer enlarges or smoothens the borehole. Some tools, like roller reamers, perform both functions.

Q4: How do I know if my stabilizer is underperforming?

Excessive tool wear, poor hole quality, and erratic bit behavior can indicate stabilizer misplacement or failure.

Q5: How often should stabilizers be inspected?

Visual inspections should occur every run. NDT (non-destructive testing) is recommended every 300–500 hours.