When you look for a downhole motor manufacturer, you see names like Halliburton, Schlumberger, Baker Hughes, Weifang Shengde, Abaco Drilling, Rival Downhole Tools, and Black Diamond Oilfield. These companies are leaders in the oil and gas field. Halliburton, Schlumberger, and Baker Hughes control about 60% of the $5 billion world market. You want motors that work well and are dependable. The table below shows important things that make top manufacturers different:

Criteria | Description |

Performance | Motors help drill faster and better. |

Reliability | They give steady results even when it is hard. |

Durability | They last a long time in rough places. |

Experience | They have many years making these tools. |

Quality Management | They are checked by ISO rules and tested for quality. |

Key Takeaways

Big companies like Halliburton, Schlumberger, and Baker Hughes lead the downhole motor market. They control about 60% of the $5 billion industry.

Pick motors for good performance, reliability, and durability. This helps drilling work well in tough places.

New technology, like smart sensors and better materials, makes motors work better and last longer. This also makes drilling safer and quicker.

To pick the best company, check for certifications and service support. Make sure they can handle your drilling needs.

It is important to do regular maintenance and watch downhole motors. This stops breakdowns and helps them last longer.

Halliburton

Overview

Halliburton is a top downhole motor manufacturer in oil and gas. The company has been around for a long time. It is well known in the market. Halliburton is different because it sells many drilling tools. You can get drill bits, reamers, hole openers, and packers from them. The company leads with new technology and good service.

You get help from Halliburton’s experience and focus on quality. They make strong downhole motors that work well in hard places.

Products

Halliburton gives you many drilling products to use. The EZ-Pilot Rotary Steerable System works for land and shallow-water jobs. This tool lets you steer the drill while it turns. You can drill faster and more accurately. Halliburton also has other motors and tools to help you finish your drilling work.

You can use these tools for many kinds of wells. Halliburton’s products help you drill safely and quickly.

Innovations

Halliburton spends money on new technology for better motors. Some motors have more power and can drill longer sideways. The company uses strong materials like Charge elastomers and tough parts. These things help motors last longer and wear out less.

Innovation | Description |

Increased Power | Motors drill longer laterals with more power. |

Advanced Materials | Charge elastomers and strong parts reduce wear and boost durability. |

NitroForce Motor | Optimizes drilling in many conditions, achieves longer runs and higher rates. |

The NitroForce motor set a record by drilling a 10,000-foot lateral. It also drills 30% faster than old motors. Halliburton made the TrueSync hybrid Permanent Magnet Motor too. This motor is up to 20% more efficient. It helps you save money on power and costs.

Tip: If you pick Halliburton as your downhole motor manufacturer, you get new ideas and good products for your drilling jobs.

Schlumberger

Overview

Schlumberger is a big name in the oil industry. The company works in over 120 countries. You can find their tools almost everywhere oil is drilled. Schlumberger cares about making new products and working better. They build advanced technologies for drilling and well construction. People trust Schlumberger because they are reliable and know a lot.

Products

Schlumberger gives you many drilling tools to pick from. They sell mud motors, drill bits, and rotary steerable systems. The PowerDrive rotary steerable system helps you drill in the right direction. The DynaForce mud motor lets you drill faster and deeper. Schlumberger’s drill bits work in many kinds of rocks. You can pick fixed cutter bits or roller cone bits. They also have MWD and LWD tools. These tools help you watch drilling conditions as you work.

Tip: Using Schlumberger’s motors and bits can help you drill faster and more accurately.

Innovations

Schlumberger spends money on new technology to solve hard drilling problems. They use digital platforms to connect drilling data and make work better. Their telemetry systems send information from the well to the surface fast. Schlumberger’s motors are made with strong materials that last longer. The company makes smart sensors that check motor health and tell you when to fix them. Every product shows Schlumberger cares about safety and doing a good job.

Digital drilling platforms

Advanced telemetry systems

Smart sensors for motor health

High-strength materials for durability

You pick Schlumberger as your downhole motor manufacturer if you want the newest solutions and help around the world.

Baker Hughes

Overview

Baker Hughes is a trusted downhole motor manufacturer. The company has helped drillers for many years. They make motors that last in tough drilling places. You can find their motors in oilfields all over the world. Baker Hughes makes tools that help you drill faster and safer.

Products

Baker Hughes gives you different downhole motor products. The Navi-Drill? and DuraMax? motors work for many drilling jobs. You can use them for directional, horizontal, or straight-hole drilling. These motors give you power and control when you need it.

You use these motors to reach oil in many wells. Baker Hughes makes each motor for different drilling problems.

Tip: Choose the right motor for your well. This helps you get better results and save time.

Innovations

Baker Hughes brings new ideas to downhole motor technology. The Navi-Drill? series works well and is reliable in hard places. The VIP? 2.0 series has special power sections for tough jobs. You can pick motors with different elastomers and lobe shapes. The Navi-Drill X-treme? series has a contoured stator with less rubber. This design makes the motor work better and lowers friction.

Innovation | Description |

Navi-Drill? series | Made for better performance and reliability in hard places. |

VIP? 2.0 series | Has power sections for tough jobs with different elastomers and lobe shapes. |

Navi-Drill X-treme? series | Has a contoured stator with less rubber for better efficiency and less friction. |

These new ideas help you when you need motors that last longer and work better in hard wells.

Weifang Shengde

Overview

Weifang Shengde is a strong company in the downhole motor industry. The company began in 1991. Now, it is a well-known downhole motor manufacturer. Their products are used in many oilfields. They work with big companies like PetroChina and Sinopec. Shengde owns 9 national invention patents and 16 utility model patents. They use advanced CNC machines for making their products. Shengde has its own lab for testing. The company wants to grow in new places and find new partners for better service.

Aspect | Details |

Industry | Downhole motor and petroleum equipment manufacturing |

Market Position | Recognized as a prominent player in the industry |

Partnerships | Strong partnerships with PetroChina and Sinopec |

Product Range | Downhole motors, oil drilling bits, progressive cavity pumps, and various fittings |

R&D Achievements | 9 national invention patents and 16 utility model patents |

Products

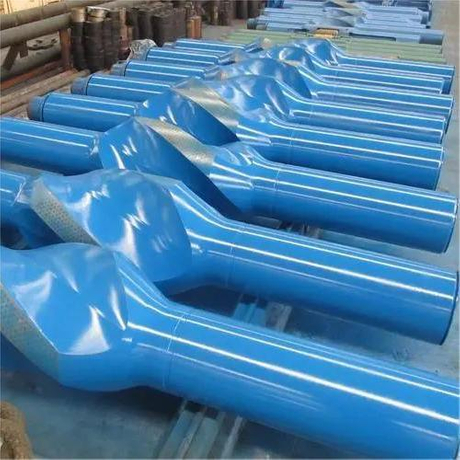

Shengde has many products for drilling. The PDC Bit helps you drill fast in soft or medium-hard rocks. The GLB single screw pump is good for getting oil in different places. Shengde’s TC bearings use special technology for long life and strong work. The downhole mud motor turns high-pressure liquid into mechanical energy. This makes drilling easier and faster. Shengde also sells hydraulic breakout units and hole openers for different drilling jobs.

Certification Type | Details |

API | API certificate obtained |

ISO9001:2015 | Quality management system |

ISO45001:2018 | Quality management system |

ISO14001 | Quality management system |

Note: Shengde’s products follow strict quality rules. You can trust their certificates for safe and steady drilling.

Technologies

Shengde’s downhole motors use advanced technology. The motors have high power and work well in hard drilling jobs. Shengde uses tungsten carbide alloy powder coating to stop wear. This keeps the motor working well in rough places. You get steady performance and long life from these motors. The motors have a wide flow range, so you can use them in many wells.

High power output for tough drilling

Great torque and reliability

Wear protection with tungsten carbide coating

Steady performance in harsh places

Shengde keeps making its technology and service better. The company builds service stations to help with repairs and support. You can count on their promise for quality and new ideas.

Abaco Drilling

Overview

Abaco Drilling is a leader in downhole motor innovation. The company is known for solving real drilling problems. Many people in oil know Abaco Drilling for its OPTIFIT stators. These stators help motors work better and last longer. If you pick Abaco Drilling, you get a partner who cares about doing a good job. The company has a strong name for making tools that help you drill better. You can find their motors in drilling projects all over the world.

Abaco Drilling always tries new ideas. This means you get motors that help you finish jobs faster and with fewer problems.

Products

Abaco Drilling has many downhole motor products. You can choose from different sizes and types for your drilling needs. Each product is made for a special job, from easy drilling to tough places. The table below shows the main products and what makes them special:

Product Type | Size Range | Distinguishing Characteristics |

Conventional | 4-3/4" - 9-5/8" | Designed for standard drilling applications. |

EVENTEK? | 4-3/4" thru 9-5/8" | Advanced technology for enhanced performance. |

Thru Tubing | 1-11/16" thru 3-3/4" | Optimized for thru-tubing operations. |

Elastomers | HPT, HPW, HPX | Specialized for high temperature, high wear, and extreme environments. |

Abaco Drilling makes motors for many drilling jobs. EVENTEK? motors use new features to give you better results. The company also makes elastomers for hard places, so you can drill in hot or rough spots.

Technologies

Abaco Drilling uses technology to help you drill smarter. The OPTIFIT stator is a big new idea. This stator helps the motor fit and work better in the well. You get more power and less time fixing things. The company uses special elastomers for high heat and tough jobs. These materials help your motor last longer. Abaco Drilling checks each motor to make sure it is good. You get motors that are strong and ready to use.

When you use Abaco Drilling’s technology, you get tools that help you work safely and well, even in the hardest wells.

Rival Downhole Tools

Overview

Rival Downhole Tools is growing fast in the oil industry. The company wants to help more drilling projects in many places. Rival opens new service centers in North America. They also make partnerships in Saudi Arabia, the UAE, and Europe. Rival tries to give better support and new drilling solutions everywhere.

Rival is moving into new areas.

The company works with partners in important markets.

Rival uses advanced drilling technology and gives local help.

Rival listens to what you need and changes quickly. Their team helps you solve drilling problems and get better results.

Products

Rival Downhole Tools has many downhole motors and drilling tools. You can find motors for easy and hard drilling jobs. Rival’s motors help you drill straight and steady. The company also sells drilling jars, shock tools, and other important tools for wells.

Product Type | Features |

Downhole Motors | High torque, strong build |

Drilling Jars | Good impact for stuck pipe |

Shock Tools | Less vibration, longer use |

Specialty Equipment | Custom tools for special wells |

You pick Rival’s tools when you want them to last in tough jobs. Rival checks every motor to make sure it is good.

Tip: Rival’s tools help you do many drilling jobs with trust.

Technologies

Rival spends money on new technology to make drilling safer and faster. You get motors made with strong materials that last longer. Rival uses careful engineering to make motors with high power and smooth work. Their tools have smart designs to lower shaking and help you drill faster.

Strong materials for long life

Careful engineering for better work

Smart designs to stop shaking

You get help from Rival’s local teams. Rival’s technology lets you finish drilling jobs faster and with fewer problems. The company keeps making its motors better so you can drill deeper and in harder places.

Black Diamond Oilfield

Overview

Black Diamond Oilfield is one of the top companies for downhole motors. Many drilling companies use their products for hard jobs. Black Diamond Oilfield is respected in the market.

Black Diamond Oilfield has a good reputation. Many customers pick them for strong motors and good support.

Products

Black Diamond Oilfield sells a few main downhole motor products. Their main products are:

You can use these motors for many drilling jobs. Mud lubricated motors work well in tough places. Sealed bearing mud motors last longer and protect better. Both types help you drill with less trouble and more trust.

Tip: Picking the right motor for your well helps you drill faster and fix things less often.

Technologies

Black Diamond Oilfield uses new technology to help you drill better. Each motor is made for power and to last a long time. The table below shows some of their main technologies:

Technology | Description |

UltraMotor | Made for long sideways wells and strong torque |

Mud Motors | Built for power and long life |

Agitators | Made to be strong and work well |

UltraMotor lets you drill longer sideways wells with more power. Mud Motors give you steady power and last a long time. Agitators help your drilling stay smooth and easy. These technologies help you get better results in hard wells.

Note: Black Diamond Oilfield keeps making its motors better so you can handle new drilling problems with confidence.

Comparative Analysis of Downhole Motor Manufacturers

Product Differences

There are many choices for downhole motor manufacturers. Each company makes products for different drilling jobs. Some motors are best for soft rock. Others are made for hard rock. Halliburton and Schlumberger have many motors for easy and hard wells. Baker Hughes builds motors that last a long time in tough places. Weifang Shengde is known for its PDC Bit that drills fast and its GLB single screw pump for getting oil. Abaco Drilling has motors with special elastomers for high heat and wear. Rival Downhole Tools and Black Diamond Oilfield make strong motors for hard work and custom needs.

You can see the main features in this table:

Manufacturer | Main Products | Special Features |

Halliburton | Drill bits, steerable motors | Fast drilling, advanced steering |

Schlumberger | Mud motors, rotary systems | Digital tools, smart sensors |

Baker Hughes | Navi-Drill, DuraMax motors | Long life, contoured stators |

Weifang Shengde | PDC Bit, GLB pump, TC bearings | Patented tech, API/ISO certifications |

Abaco Drilling | EVENTEK, OPTIFIT stators | High-temp elastomers, fit optimization |

Rival Downhole Tools | Downhole motors, jars | High torque, local support |

Black Diamond Oilfield | Mud motors, agitators | UltraMotor for long wells |

You can find a motor for every drilling job. Some are for shallow wells. Others are for deep or sideways drilling. Each company has something special to offer.

Technology Strengths

You want motors that work well and are safe. New technology helps you drill faster and safer. Halliburton uses Charge elastomers and hybrid magnet motors for more power. Schlumberger uses smart sensors and telemetry to share drilling data. Baker Hughes makes motors with special stators and elastomers for hard wells. Weifang Shengde uses tungsten carbide coatings and strong bearings for long-lasting motors. Abaco Drilling’s OPTIFIT stator gives a better fit and more power. Rival Downhole Tools and Black Diamond Oilfield use strong materials and smart designs.

This table shows how technology helps motors work better and last longer:

Manufacturer | Technology | Efficiency Improvement | Reliability Improvement |

NOV | Vector Series 50 | Up to 2x more power to bit | Superior directional performance |

Halliburton | NitroForce Motor | 30% faster drilling | Longer runs, less wear |

Schlumberger | PowerDrive System | Accurate steering, faster | Smart sensors, real-time data |

Baker Hughes | Navi-Drill X-treme | Lower friction, better output | Contoured stator, longer life |

Weifang Shengde | TC bearings, coatings | Steady performance, less wear | High durability, corrosion resistance |

You can see that new technology makes motors stronger and last longer. You get more work done with fewer problems.

Choosing the Right Manufacturer

You need to pick a motor that fits your drilling job. Check if the motor is safe in risky places. Look at how well it keeps out water and dust. Motors with overload and overheat protection shut off if there is a problem. Good design makes motors easy to install and fix. Smart management lets you check motor health from far away. Simple controls make motors easy to use. You want motors that do not cost too much to buy or run. Motors should also be good for the environment.

Here is a table to help you choose:

Factor | Description |

Explosion-Proof Performance | Safe operation in hazardous environments |

Protection Level | Prevents water, dust, and contaminants |

Overload and Overheat Protection | Automatic shutdown in abnormal situations |

Structural Design | Easy installation and repairs |

Intelligent Management | Remote monitoring and fault diagnosis |

Operation Interface | Simple controls for easy use |

Procurement Costs | Reasonable prices with good performance |

Operating Costs | Low energy and maintenance costs |

Environmental Performance | Meets environmental standards |

Pick a motor that matches your drilling needs. If you drill deep or in hot places, choose motors with high-temperature elastomers and strong bearings. For fast drilling, pick motors with new technology and good performance. Look for companies with good service and repair stations. You get better results when you choose a company that helps you solve problems.

Tip: Always ask about service and warranty before you buy. Good support helps keep your drilling going.

Conclusion

You have lots of options when picking a downhole motor manufacturer. Every company has something special to offer. Some use new technology. Others give strong support or make reliable motors. To choose the best one, look at important things:

Metric | What to Check |

Mean time between failures | Pick motors that do not break often |

Runs-to-failure | Make sure motors work well every time |

Certifications | API Q1 and ISO 9001 mean good quality |

You should ask for help before you start your job. It is good to have experts you can call if you need them. After you finish, check how the motor did. Think about new trends like being green and using more machines. Always pick a company that sells good motors and helps you after you buy.

FAQ

What is a downhole motor used for in oil drilling?

A downhole motor turns the drill bit underground. It helps you drill wells faster. You can reach oil in hard places with it.

How do you choose the right downhole motor manufacturer?

Pick a company with strong products and good service. Make sure they have trusted certifications. Check if they support you and have reliable motors.

Why do certifications like API and ISO matter?

Certifications mean the company follows safety and quality rules. You can trust motors with these certificates. They are made to work well.

How often should you maintain a downhole motor?

Check and service your motor after every drilling job. Regular care helps stop breakdowns. It keeps your motor working longer.